By Rod Hozack, Partner at Oliver Wight Asia Pacific

In our previous blog, we discussed what Integrated Tactical Planning is and when you should consider implementing it. In this blog, we address the foundation of effective ITP – the ‘time fence’.

What are time fences?

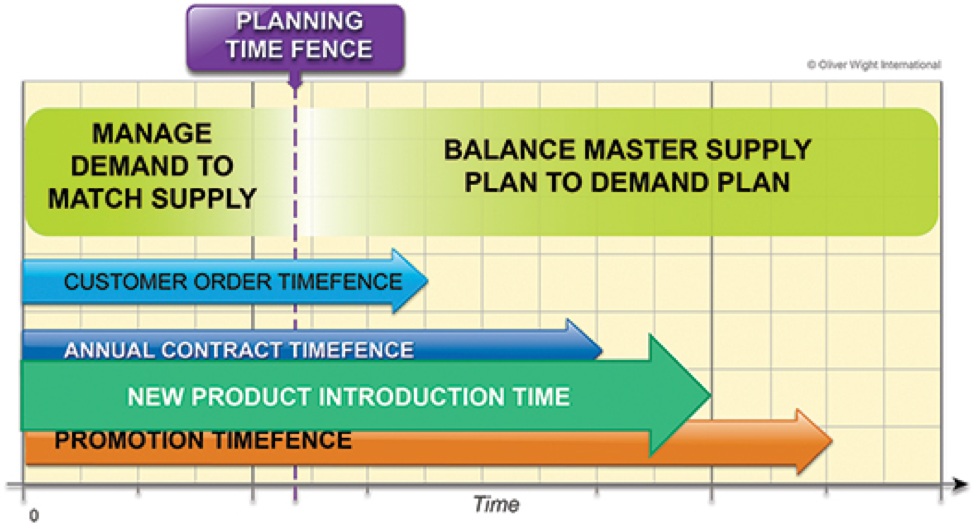

The time frame for Integrated Tactical Planning is usually referred to as the ‘time fence’ or the ‘planning time fence’. The simplest way of defining this planning time fence is the time from ordering the longest lead-time material to having the finished goods ready for shipping to a customer or a warehouse. A time fence segregates ‘planning’ from ‘control and execution’ at the point we spend money. A more precise way of looking at this is to ask, “Where do we start spending money on variable and semi-variable expenses?” For example, in a manufacturing or physical goods environment, the lead time for purchasing materials and products could be several months for items sourced overseas, or weeks, if they are locally sourced.

How many time fences are there?

Note that it’s plural – there needs to be multiple times fences for ITP depending on the type of decisions that need to be made. As shown in the figure, other time fences that should also be considered include: managing customer order expectations, contractual obligations, trade spend and promotional planning, and new product introduction.

Whereas the monthly Integrated Business Planning process manages resource and supply to meet the demand plan, the key concept of the ITP process is managing demand to meet the resource and supply plan inside the planning time fence. Unfortunately, without time fences being defined, communicated, agreed, and being worked to, the IBP process will attract senior managers to spend more time than needed, in the here and now, and the interface with strategy will remain a once-a-year thing.

Whereas the monthly Integrated Business Planning process manages resource and supply to meet the demand plan, the key concept of the ITP process is managing demand to meet the resource and supply plan inside the planning time fence. Unfortunately, without time fences being defined, communicated, agreed, and being worked to, the IBP process will attract senior managers to spend more time than needed, in the here and now, and the interface with strategy will remain a once-a-year thing.

In Part 3 we look at how plans are being managed through Integrated Tactical Planning.